It's Your Building's Immune System—But What If It's Sick?

You trust your fire sprinkler system to be the silent guardian, ready to activate at a moment's notice. But what if, deep inside the hundreds of metres of steel pipe, a hidden threat is compromising its integrity? I'm not talking about external damage; I'm talking about an enemy that grows from the inside out: corrosion.

For decades, assessing the internal condition of sprinkler pipework was a grim, disruptive affair. We'd have to isolate a section, drain it, and physically cut out a coupon of pipe for a visual inspection. It's expensive, creates downtime, and gives you a snapshot of just one tiny piece of a massive network. It's like trying to diagnose a patient's health by looking at a single cell. In New Zealand, where compliance with NZS 4541 is non-negotiable, we've needed a smarter way forward.

From Destructive Guesswork to Digital Certainty

The core problem is twofold. In traditional wet pipe systems, trapped oxygen is the fuel for corrosion. In dry or pre-action systems, residual moisture after testing creates a perfect breeding ground for Microbiologically Influenced Corrosion (MIC)—a particularly aggressive form where bacteria accelerate the degradation of the steel. The result? Pin-hole leaks, reduced hydraulic performance, or catastrophic pipe failure during a fire event.

Fortunately, technology has moved us beyond the hacksaw. Modern corrosion monitoring has shifted from being reactive to proactive, leveraging two key technologies:

- Ultrasonic Testing (UT): Non-destructive handheld devices can now send sound waves through a pipe wall and measure its thickness with incredible precision. An engineer can take dozens of readings across a system in a day, building a detailed map of potential problem areas without ever draining a drop of water.

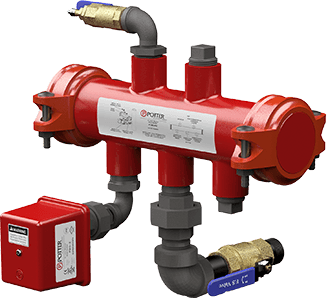

- IoT-based Sensors: The real game-changer. Devices like the Potter PCMS-RM (Corrosion Monitoring Station) are installed directly onto the sprinkler riser. These stations hold metal 'coupons' that are designed to corrode at a predictable rate, simulating the conditions inside the pipe. More advanced models include probes that, once corroded through, send a supervisory signal to the fire alarm panel. It's a direct, 24/7 alert that your system needs attention.

The Business Case for Proactive Monitoring

Why does this matter to a building owner or facility manager in Auckland or Christchurch? It’s about managing long-term risk and cost. An emergency pipe replacement can cost tens of thousands of dollars in repairs and business interruption. A proactive monitoring strategy, however, costs a fraction of that and allows for planned maintenance.

It also provides a robust, data-driven method for satisfying the internal inspection requirements of NZS 4541. Instead of just ticking a box with a single pipe sample, you can present FENZ or your compliance inspector with a trend-line of data showing the health of your entire system over time. This isn't just best practice; it's smart asset management.

The next time you look at a sprinkler head, don't just see the device. Think about the network behind it. The move towards intelligent, non-invasive monitoring ensures that your building's first line of defence against fire is never silently bleeding out from the inside.