That Sinking Feeling in a Cold Storage Design

Ever had that moment staring at the plans for a massive new cold storage facility? You’ve got a -20°C freezer box sitting inside a 20°C ambient warehouse structure. The roof will expand and contract with the sun, the freezer box will heave and settle, and somewhere in that shifting interface, you need to run a dry sprinkler pipe through a perfectly airtight seal. For years, this meant rigid steel pipe, custom arm-overs, and a constant battle against condensation and ice jacking that could compromise the entire system. It’s a classic fire engineering headache. But what if the solution wasn’t more rigidity, but engineered flexibility?

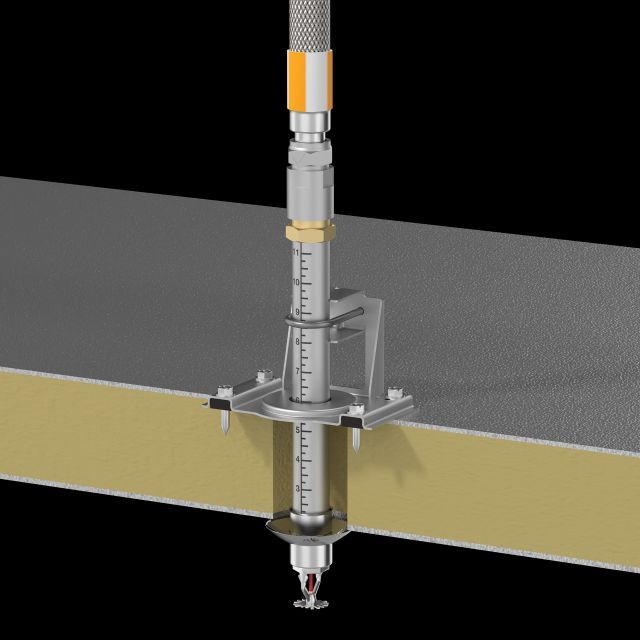

Tech Showcase: The Victaulic VicFlex Style AB6 Bracket

Enter the Victaulic VicFlex system, specifically the Style AB6 Adjustable Bracket. At first glance, it’s a simple assembly: a sturdy bracket, a U-bolt, and a clever mounting plate. But paired with the Series AH2 braided stainless steel hose, it becomes one of the most elegant solutions to the cold storage problem, and it brings some serious benefits to our seismically-active New Zealand sites.

This isn’t just a floppy pipe. It’s a fully engineered system designed to allow for significant differential movement. While the building roof above is doing its thing, the freezer ceiling below can remain static, and the flexible hose connecting the branch line to the dry sprinkler head simply absorbs the displacement. This prevents stress fractures at the connections and, crucially, protects the integrity of the vapour seal around the sprinkler barrel. The result? No ice buildup, no compromised seals, and a dry system that remains reliable.

Engineered for the Real World

The real beauty of the AB6 is in its installation design. Victaulic clearly spent time talking to the folks on the tools. The entire assembly is designed for a one-person install from *above* the ceiling grid. No more awkward multi-person lifts or wrestling with threaded pipe in a tight ceiling space.

The key specs tell the story:

- Hose: The Series AH2 is a 304 stainless steel braided hose with a maximum working pressure of 1200 kPa (175 psi).

- Flexibility: It has an impressive minimum bend radius of 178mm (FM Approval), allowing it to navigate around other services in a cluttered ceiling plenum with ease.

- Adjustability: The AB6 bracket accommodates a huge range of ceiling thicknesses, clipping into place and providing a stable, secure anchor for the sprinkler head. One installer can fly through a grid, mounting brackets and connecting hoses at a pace that’s simply impossible with traditional hard pipe.

This isn't just a marginal gain. A press release from Victaulic cites an installer who, using the AB6 system, could install 20-25 dry cooler heads in an hour. That’s a game-changing productivity claim that directly impacts project timelines and labour costs.

The NZ Angle: More Than Just a Dropper

So, it’s great for freezers. But why should every NZ-based fire engineer have this in their design arsenal? The answer is seismic resilience.

We live and work on the “shaky isles.” NZS 4541, our guiding standard, places a heavy emphasis on ensuring life safety systems can withstand seismic events. Clause 3.12 is all about seismic restraint. Traditionally, for a rigid dropper in a suspended ceiling, this can mean adding seismic braces or ensuring clearances that can be complex to coordinate and install.

A flexible dropper system like the VicFlex offers an alternative path to compliance. By its very nature, it decouples the sprinkler head from the rigid branch line. It allows the ceiling grid to move independently of the pipework during a quake, reducing stress on the fittings and preventing failures. This inherent flexibility can simplify seismic design, reduce the need for extensive bracing on the drops themselves (though the main lines still need it, of course), and ultimately lead to a more robust, resilient system that’s more likely to be functional after an event. It’s a perfect example of designing *with* movement in mind, not against it.

The Bottom Line

The Victaulic VicFlex Style AB6 isn’t just a component; it’s a design strategy. For the designer, it solves a persistent problem in challenging environments like cold storage. For the installer, it’s a massive labour and time saver. And for the building owner in New Zealand, it delivers a faster build and a more seismically resilient fire protection system. It’s a testament to how focusing on a small piece of hardware can have an outsized impact on a project's safety, speed, and resilience.